Cut List Optimizer for Woodworkers

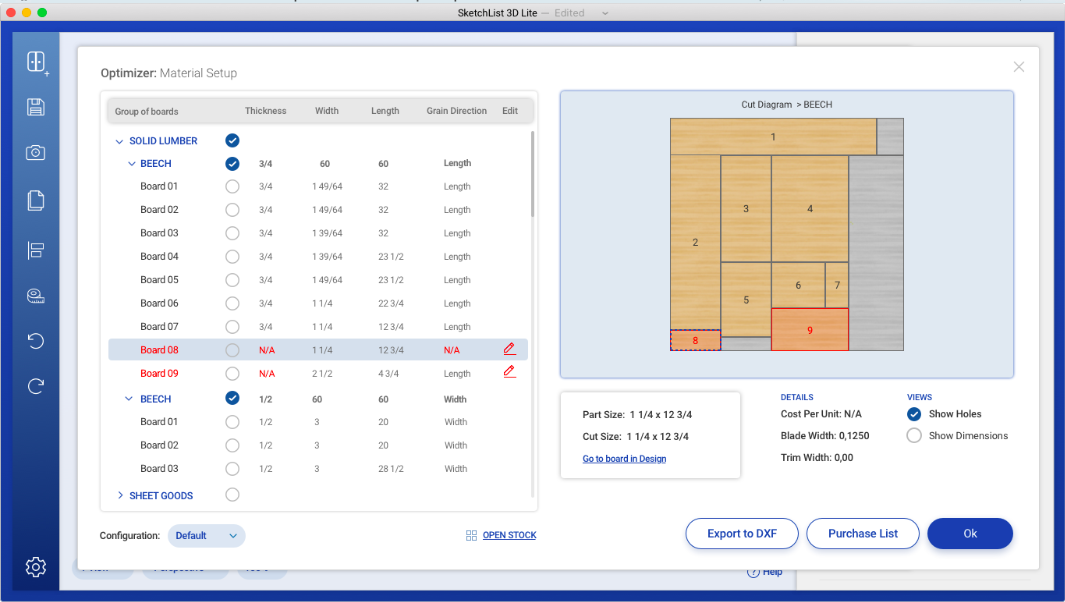

Are you a woodworker? Are you tired of spending hours manually creating your cut list? There are tools that can help you. The material optimizer is one and a cut list [or part list] is another. SketchList 3D is unique because it integrates both an optimizer and a cut list report into the process of designing your work. One and the same.

What is a Cut List Optimizer?

A cut list optimizer is a tool that helps woodworkers create the most efficient cut list for their projects. It uses algorithms to analyze and optimize the dimensions of all the pieces you need to cut, making sure that you get the most out of every piece of wood. It simplifies the process of creating a cut list, allowing you to spend more time actually doing the woodworking instead of calculating and planning.

Benefits of Using a Cut List Optimizer

Using a cut list optimizer can save you a lot of time, energy, and materials. It can help you get the most out of every piece of wood, ensuring that you don’t waste any resources. It can also improve the accuracy of your cut lists, allowing you to make precise cuts and achieve better results. Finally, it can help you to plan your projects more efficiently, allowing you to maximize efficiency and minimize waste.

Features of a Cut List Optimizer

A good cut list optimizer should offer a wide range of features.

- It should be able to analyze and optimize the dimensions of any piece you need to cut, as well as identify common patterns and repeatable elements.

- It should also be able to identify the most efficient way to cut your pieces, taking into account any restrictions or limitations you have.

- Finally, it should offer a simple and intuitive interface, allowing you to quickly and easily create and edit your cut list.

Those basics will get you by. But other features such as setting the blade width [kerf size], allowing filtering of the report by material type and assembly, and producing a purchase list of materials needed for a given job are very nice to have.

The Process of Creating a Cut List

Creating a cut list is a complex process. It involves measuring and calculating the dimensions of all the pieces you need to cut, as well as identifying common patterns and repeatable elements. It can be difficult to do this manually, as it takes a lot of time and energy.

With SketchList the complexity goes away. Each board you add to your design is assigned to a material. The software checks to make sure the new board actually fits onto the material. As you move along with your design adding new boards, those boards are separated by material types, species, and sizes and mapped onto the material. For example all the parts on 1/4 inch plywood map again the material you specify for them. The optimization process is the design process.

How a Cut List Optimizer Works

A cut list optimizer works by analyzing and optimizing the dimensions of all the pieces you need to cut. It takes into account any restrictions or limitations you may have, as well as any common patterns or repeatable elements. It then identifies the most efficient way to cut the pieces, making sure that you get the most out of every piece of wood.

How to Use a Cut List Optimizer

Using a cut list optimizer is easy. All you need to do is input the dimensions of the pieces you need to cut, as well as any restrictions or limitations you may have. The optimizer will then analyze and optimize the dimensions, identifying the most efficient way to cut the pieces. You can then use the optimized cut list to make precise and accurate cuts.

Again with SketchList you are inputting the parts sizes and you virtually cut and place the board into your work. So no extra steps are needed.

Advantages of a Cut List Optimizer

Using a cut list optimizer can offer a number of advantages. It can save you a lot of time and energy, as it automates the process of creating a cut list. It can also improve the accuracy of your cut list, allowing you to make precise and consistent cuts. Finally, it can help you to plan your projects more efficiently, allowing you to maximize efficiency and minimize waste.

Popular Cut List Optimizers

There are a number of popular cut list optimizers available on the market. Some of the most popular include CutList Plus. It offers a range of features, allowing you to easily and quickly create and edit your cut list. However it does not include a design function so you must first draw out your design, make a parts list with sizes, and enter them into the spreadsheet for importing.

Conclusion

If you’re a woodworker, then a cut list optimizer is a must-have tool. It can save you a lot of time and energy, as well as improve the accuracy of your cut list. It can also help you to plan your projects more efficiently, allowing you to maximize efficiency and minimize waste. So, what are you waiting for? Try a cut list optimizer today and unlock new levels of efficiency in your woodworking projects!