Are you interested in incorporating glass panels into your cabinet design software but unsure how to go about it?

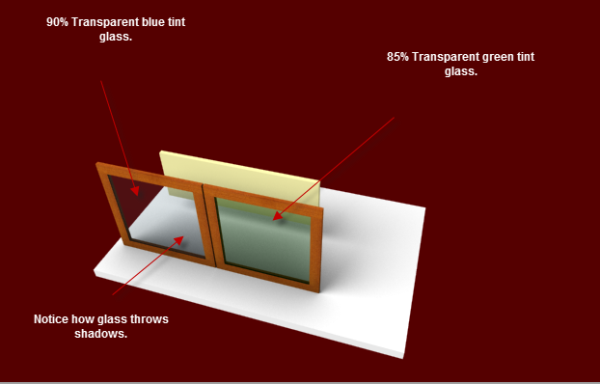

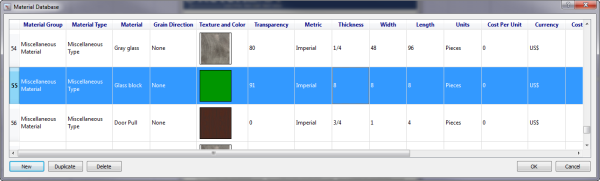

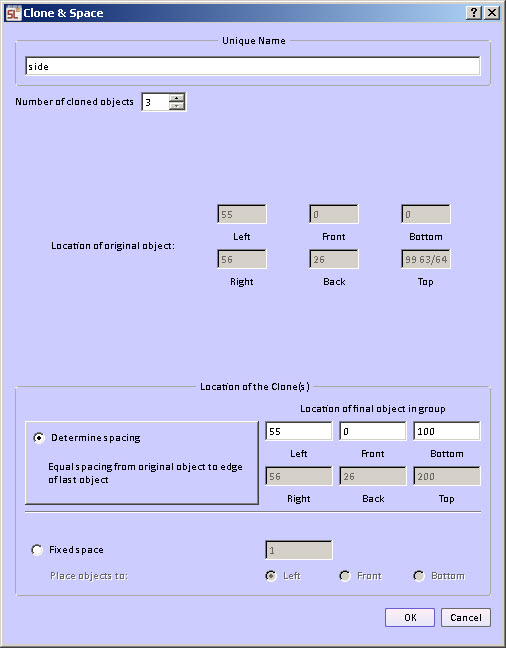

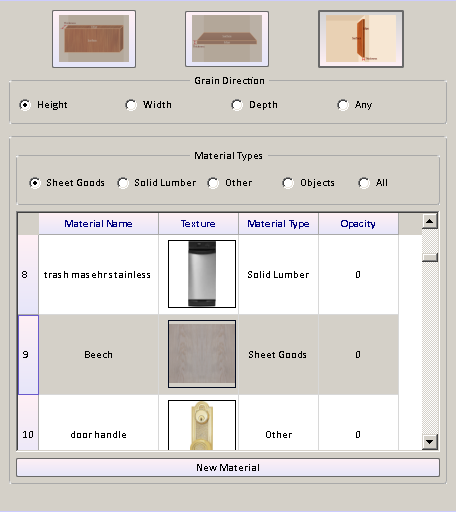

SketchList 3D allows you to use panels in cabinet designs by creating a material and setting the transparency percentage. You can choose the color of the glass by selecting the color of the material from the color list. To give you an idea of how glass can be used in your designs, let’s take a look at an example of glass front doors.

Incorporating Glass Panels in Your Assembly

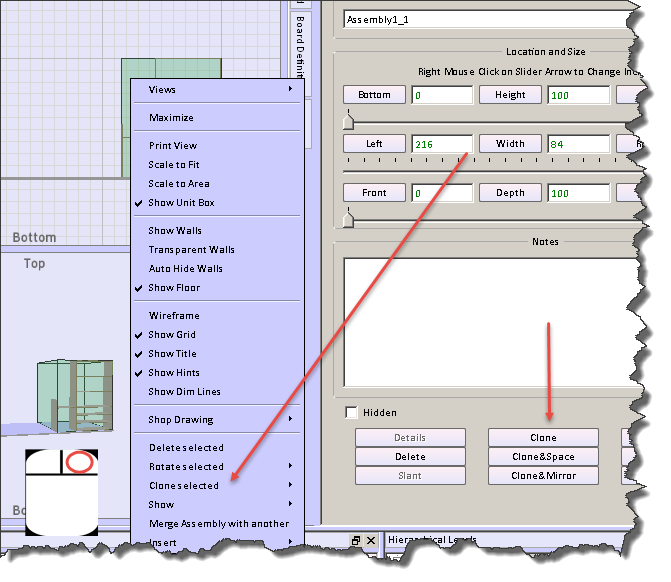

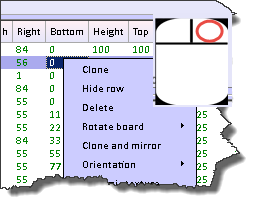

Let’s say we have two different types of glass panels, one blue and the other green, used with transparencies set at 80% and 91%, respectively. Insert The glass panels become and inserted as “boards” in the assembly. The glass serves as the material for that board. You can contour or shape the glass to fit your design needs. You can even shape different pieces of glass to create a stained-glass effect.

Experimenting with Different Design Elements

You can vary the color of the glass, the percentage of transparency, the background color, and the angle from which the 3D rendering to create different looks for your designs. The angle of the 3D rendering affects the look of the design due to the differing shadows cast by the light source. SketchList 3D allows you to experiment with all these design elements until you achieve the desired result.

Expanding Your Design Options

SketchList 3D does more than cabinet design software. You can use the software to create designs using any material, whether it’s glass, metal, plastic, or any other material. With SketchList 3D, you have the freedom to create designs that truly reflect your creativity.

In Summary

Are you looking to incorporate glass panels into your cabinet designs? SketchList 3D cabinet design software is a great option. With its user-friendly interface and ability to work with various materials, SketchList 3D meets your unique needs.