How to Increase Efficiency in Cabinet Production with Optimized Material Layouts and Cut Lists

How to Increase Efficiency in Cabinet Production with Optimized Material Layouts and Cut Lists

Is your cabinet production inefficient?

Cabinet production is no easy task. For a company to produce the number of cabinets needed to fulfill all orders on time, you must have a well-oiled machine. Cabinet design software is vital.

Many cabinet-producing companies do not optimize their processes to help them increase efficiency. Are you looking to improve your custom cabinet production process? One solution may be optimized material layouts and cut lists.

This guide will help you optimize your processes to produce cabinets more efficiently.

The Importance of Optimized Material Layouts

Optimizing material layouts is about creating an efficient process that saves time and money while minimizing waste. The key to effective material optimization is ensuring that parts are strategically arranged on the sheet. Ensure that every piece is accounted for and that there is no wasted space.

Doing this will reduce material waste, decrease the number of sheets required, and minimize errors or misplacements.

Optimizing material layouts often involves using advanced software solutions in the automation process. This woodworking design software provides detailed layouts and helps create designs. It does this while considering waste reduction, layout efficiency, and automation.

With optimized material layouts, you can quickly determine the layout of your cabinets to determine the number of sheets of wood required. The software will give you accurate material requirements, including hardware and finishing supplies, that you must prepare in advance.

Creating Efficient Cut Lists

A cut list is a detailed inventory of all the parts that go into a project, typically including dimensions and quantity. Creating an accurate and efficient cut list ensures you are using the right amount of material without wasting any. This helps reduce the time spent cutting and keeping track of inventory.

To create a cut list, you need accurate measurements and detailing. This allows you to determine the number and size of components needed.

Cut lists are critical to the efficiency of your custom cabinet production process. They help your team keep an accurate inventory of materials and ensure they are used correctly.

You can also use software solutions to develop a cut list, reducing the time needed to determine the number and size of components needed. This way, you can ensure the proper allocation of materials and avoid the wastage of expensive resources.

Software Solutions

Automation has revolutionized the cabinet industry, and woodworking is no exception. The use of technology in optimizing material layouts and the creation of efficient cut lists have improved the productivity and quality of custom cabinet production.

Software solutions have revolutionized the way cabinet production is managed. To increase efficiency, cut lists and material layouts are optimizable with furniture design software. Cut lists can be quickly and accurately generated with specialized software. This allows for speedier production of cabinets that meet precise measurements and requirements.

Software can also optimize material layouts. This enables manufacturers to use proper amounts of material and optimize their inventory. By using software solutions, cabinet manufacturers can increase their efficiency. They can also reduce expenses, making a more productive and profitable business.

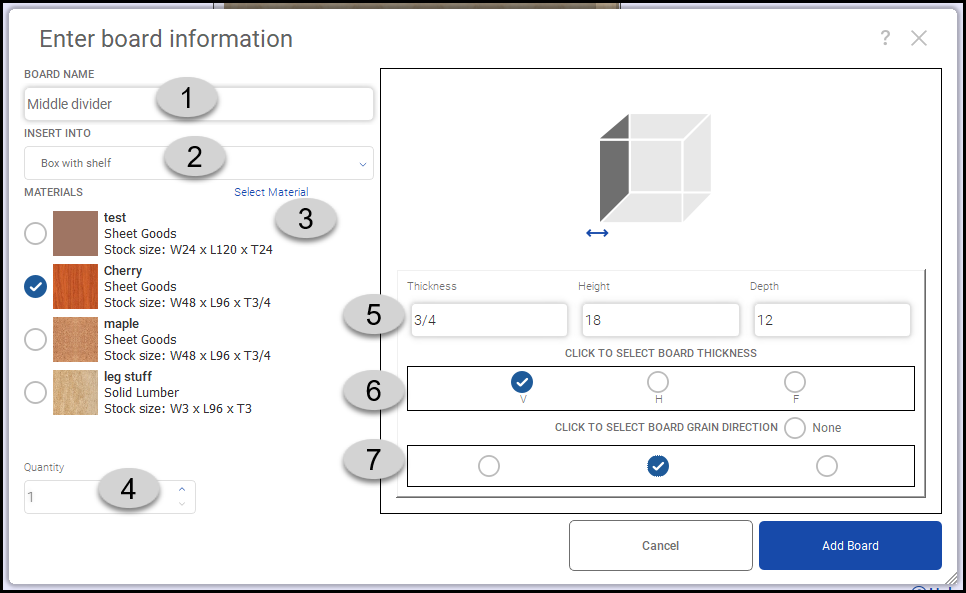

The availability of advanced 3D software for custom cabinets and woodworking designing makes the production process easier. With photo-like 3D images, shop drawings, cut lists, optimized layout diagrams, and a DXF file that we can use for CNC cutting, we can now streamline the process and increase efficiency significantly.

SketchList makes it easier to visualize components arranged on sheets. With this kind of software, you can easily move components around and adjust the placement to cut waste.

Accurate and efficient cut lists by CNC electronics automate cutting, further optimizing production. With software solutions for optimizing material layouts and cut lists, custom cabinet makers and woodworkers can save time and money.

Advantages of Reducing Waste

Using optimized cut lists and material layouts is one of the best ways to increase the efficiency of cabinet production and reduce waste. By optimizing the list and layout of all components used in the production process, you can use the production process and cost more efficiently and with minimal waste.

When the wood components, hardware, and other materials are laid out in the correct configuration, you can complete the process of cutting and assembly quickly. Furthermore, wasting fewer pieces of raw materials reduces costs. As a result, manufacturers can produce higher-quality products in a shorter period of time, providing overall cost savings.

Reducing waste helps to cut costs associated with raw material disposal. It also reduces the impact the production process has on the environment.

By optimizing material layouts and efficient cut lists, you can reduce waste. Reducing waste is not only environmentally friendly but also saves money and increases revenue. Inefficient use of materials can impact the budget of your projects and hinder profitability. Effective material optimization can help you save money by using fewer sheets and reducing your material costs.

Besides reducing material costs, optimizing material layouts and cut lists enhances customer satisfaction. Optimized designs ensure that components fit together and ensure the preciseness of each part, creating a superior final product. Minimizing waste also helps you reduce clean-up time and disposal costs. This frees up resources for other aspects of your operations.

Let SketchList 3D Help You Optimize Your Business

Optimized material layouts and cutting lists can improve the custom cabinet production process. Using advanced software solutions, custom cabinet makers and woodworkers can streamline production processes. They can also reduce material costs and increase revenue.

With SketchList 3D, you’ll have everything you need to create better woodworking designs. Our software has helped over 5,000 woodworkers just like you with everything from furniture design to custom cabinet production while improving efficiency and reducing waste. Whether you’re working with an independent client or a commercial property on office design, we’re here to help.

The best part is that you can try it today for free for 30 days! Sign up today and see why SketchList 3D is a trusted tool in the woodworking industry.