The world of woodworking has embraced technology with open arms. Computer-aided design (CAD) stands out in this tech-savvy workshop. It transforms ideas into tangible realities. For woodworkers, CAD isn’t just a tool; it’s a game-changer, especially when managing production. CAD reports are crucial in ensuring that each project is executed with precision.

What Are Woodworking CAD Reports?

Woodworking CAD Software reports are detailed documents generated from your CAD designs. They aren’t just blueprints; they provide insights into every aspect of a woodworking project. These reports contain dimensions, materials, and the step-by-step assembly process. They offer a comprehensive guide that ensures the project aligns with the original vision.

Types of CAD Reports in SketchList 3D

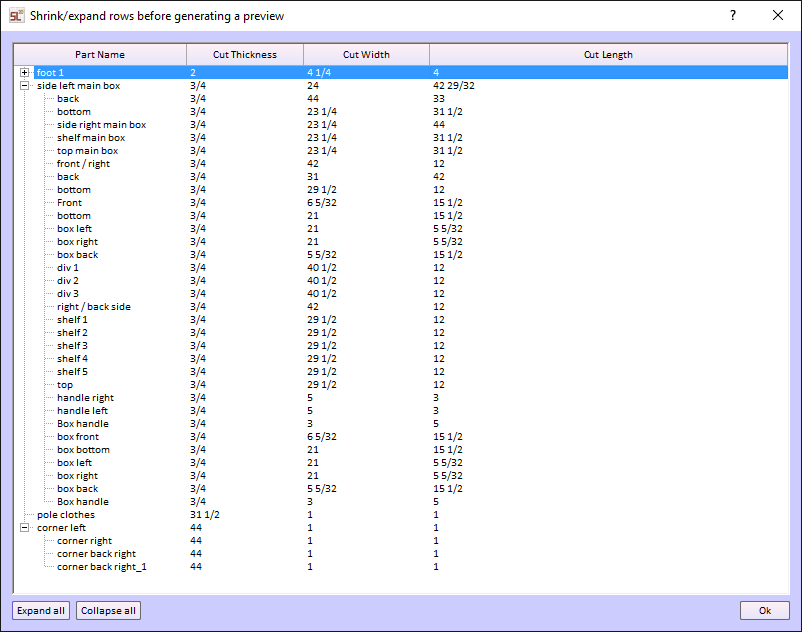

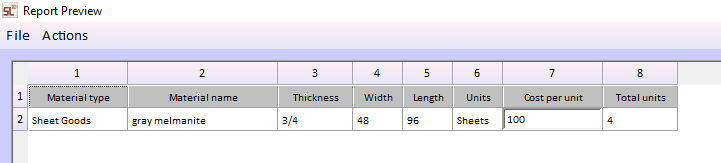

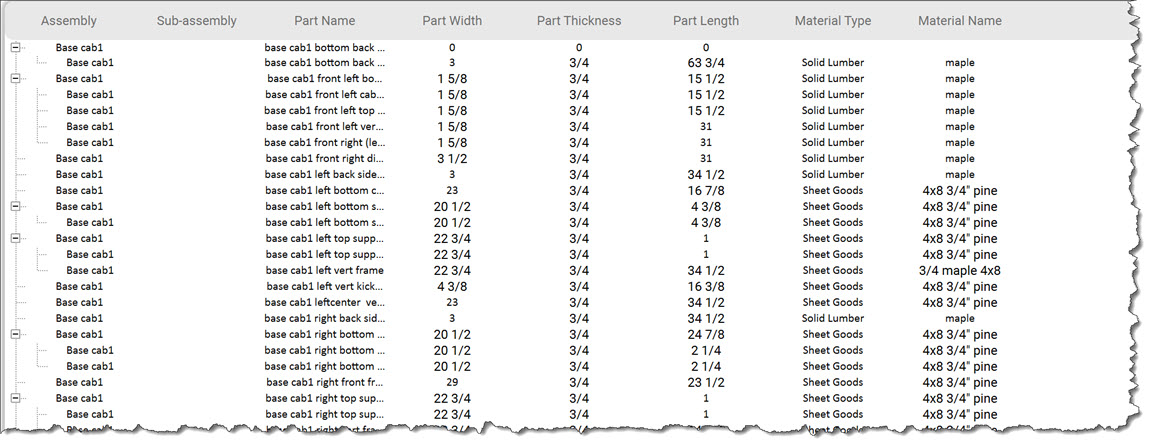

- Material Lists: These reports list all materials needed for the project, ensuring nothing is left out.

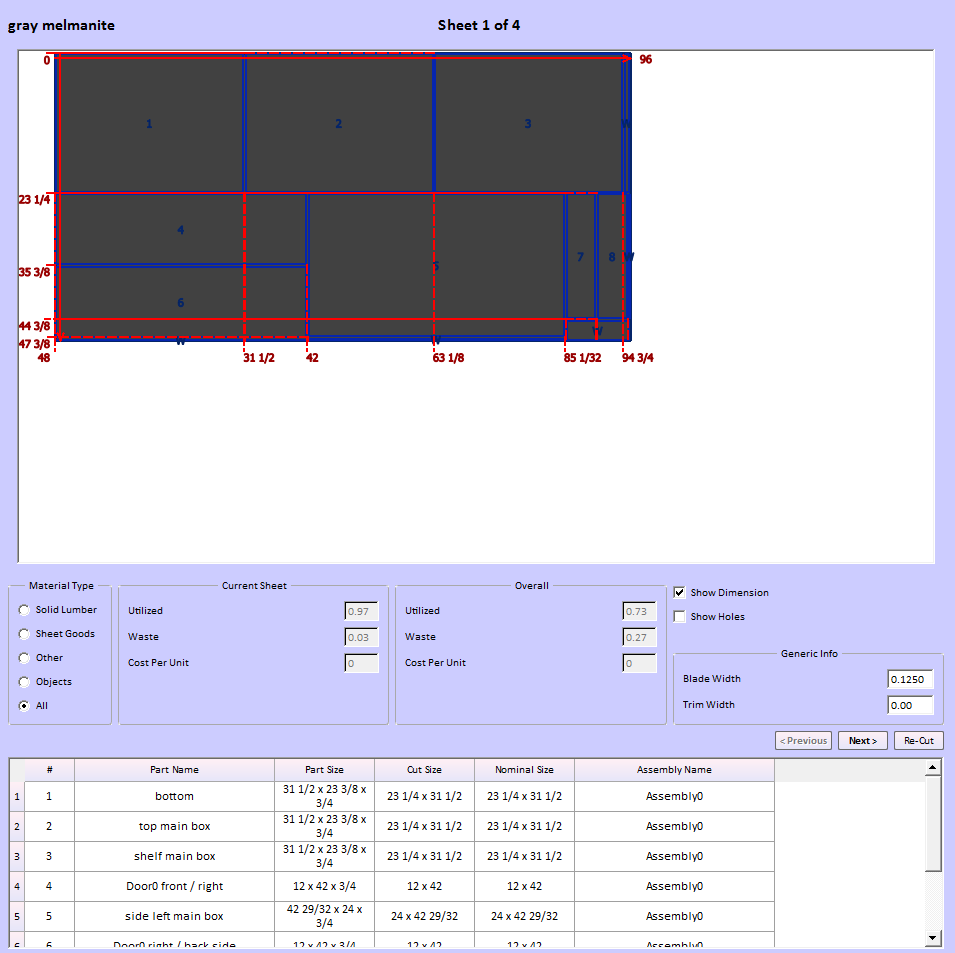

- Cutting Diagrams: Visual guides showing how each piece interacts with the others, minimizing waste during cutting.

- Cut Lists: Report the lists of every project part by type and species, including sizes.

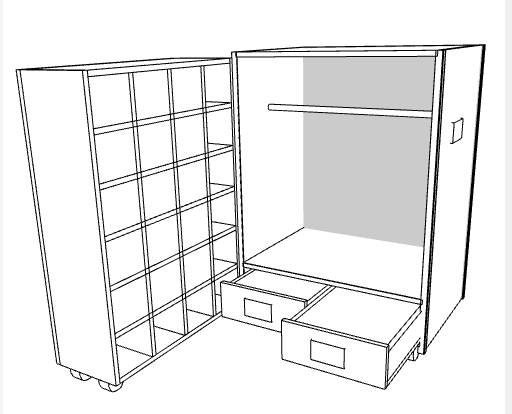

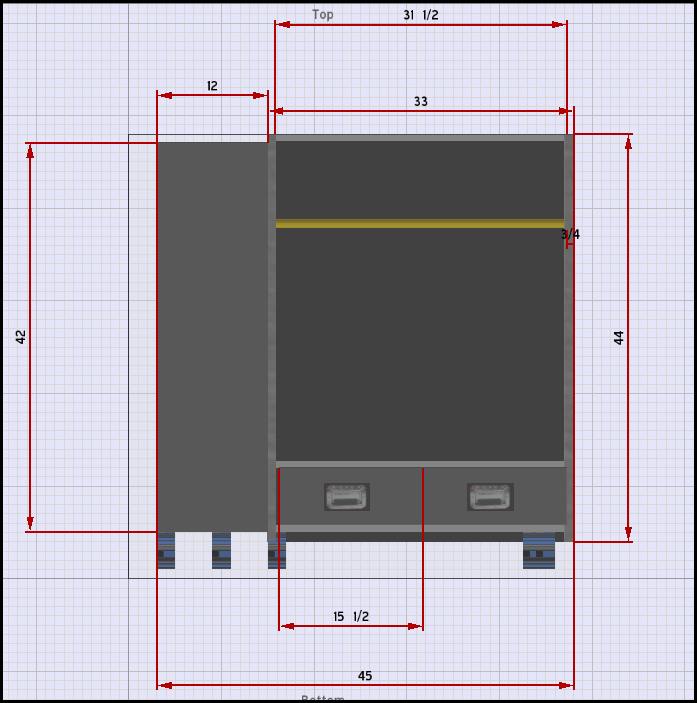

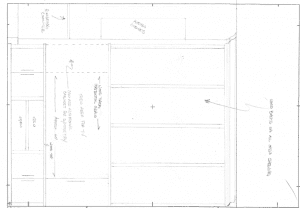

- Shop Drawings: Fully dimensioned shop drawings.

Benefits of Using CAD Reports in Woodworking

Integrating CAD reports into woodworking design has many benefits. Whether you’re designing a simple chair or a complex cabinet, CAD reports are indispensable.

Enhanced Accuracy and Precision

Before CAD, measuring twice and cutting once was the mantra. With SketchList 3D reports, accuracy is now in-built. By relying on precise data from detailed reports, woodworkers can avoid errors. The precision offered by woodworking CAD software can be a significant advantage. Learn more about how CAD offers precision and visualization in woodworking.

Streamlined Workflow

Efficiency is synonymous with woodworking CAD reports. From planning to execution, every stage benefits from calculated insights. These reports help map out a project’s journey, reducing the likelihood of mid-project halts.

Best Practices for Creating Woodworking CAD Software Reports

Creating a CAD report requires careful planning and execution. Here are some best practices to keep in mind:

- Choosing the Right Software

- Not all CAD tools are created equal. Some woodworking CAD software excels in 3D modeling, while others shine in 2D drafting. Software like SketchList 3D is popular among woodworkers for its simplicity and efficiency. For beginners, SketchList 3D offers an intuitive interface.

- Integrating Feedback and Revisions

- Woodworking is a craft, and no two projects are the same. Incorporating feedback into your reports is essential for improvement. Revisions help tailor the project to specific needs and rectify potential issues early on. Design and reporting must integrate with design, as in SketchList 3D. Every design change is automatically reflected in all the reports. If not, changes in the drawings may not make it to the cutlist, and it is out of sync with the design. This is not good.

Conclusion: The Future of Woodworking CAD Software Reports

The future of woodworking lies in seamless integration with technology. CAD reports have shifted from being optional to essential in modern woodworking. They represent a blend of tradition and innovation, ensuring craftsmanship never loses its touch. Accordingly, as technology evolves, these reports will undoubtedly become even more integral, with precision and creativity. Now, consider whether you ever imagined that tech would profoundly shape craftsmanship.

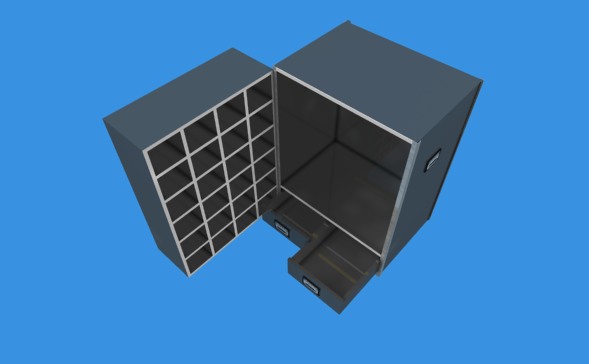

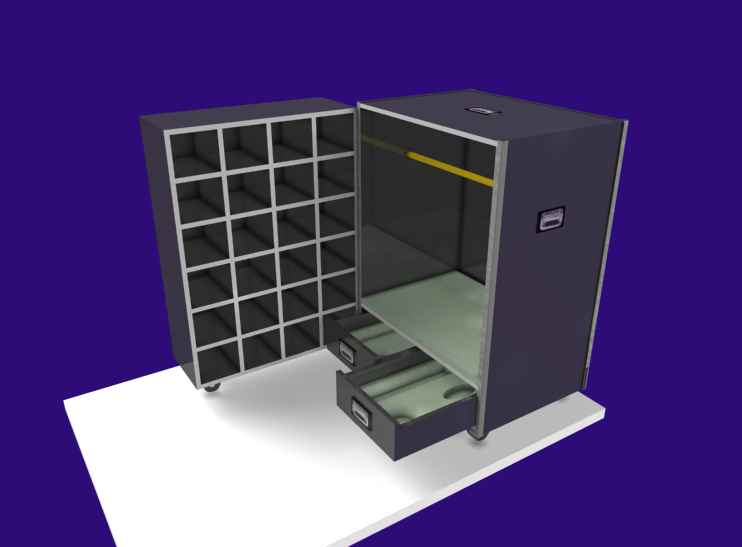

Furniture design software helps users visualize their design by providing a digital mock-up of the project. This allows you to make alterations and view the design layout before making it in a physical form.

Furniture design software helps users visualize their design by providing a digital mock-up of the project. This allows you to make alterations and view the design layout before making it in a physical form. Furniture designers and woodworkers can use the software’s visual 3D design interface to transform their raw ideas into fully-functioning cabinets and furniture. It has a variety of features that help simplify even the most complex design projects with ease.

Furniture designers and woodworkers can use the software’s visual 3D design interface to transform their raw ideas into fully-functioning cabinets and furniture. It has a variety of features that help simplify even the most complex design projects with ease.