In today’s competitive woodworking industry, precision, efficiency, and speed are key to standing out. Whether you run a professional woodworking shop or create high-end custom pieces as a serious hobbyist, the ability to design quickly and accurately can make all the difference. Traditional sketching methods or complex CAD software can slow you down, leading to inefficiencies and costly mistakes. That’s why many woodworkers are turning to digital solutions, particularly an app for woodworking design that simplifies the process and maximizes productivity.

The Challenges of Traditional Woodworking Design

To draft their projects, many custom woodworkers still rely on hand-drawn sketches, graph paper, and basic calculations. While this may work for small, simple pieces, it becomes increasingly inefficient for detailed, high-end woodworking projects. Challenges include:

- Time-consuming revisions – If a client requests changes, you may need to redraw entire plans.

- Errors in measurements – Even minor miscalculations can lead to wasted materials and extra labor.

- Difficulty visualizing the final product – Two-dimensional sketches don’t always convey the whole picture.

- Limited ability to communicate with clients – Without a clear 3D representation, clients may struggle to understand the final design.

By adopting an app to draw woodworking plans, woodworkers can eliminate these inefficiencies and streamline their design process.

The Need for a Smarter, Faster Design Tool

Woodworkers need a solution that allows them to generate, modify, and present designs quickly. However, traditional CAD software is often too complex, requiring extensive training and time investment. This is where an app for woodworking designed for ease of use comes into play.

What to Look for in a Woodworking Design App

When choosing the right app for woodworking design, consider the following features:

- Ease of Use – The software should be intuitive, allowing even those without a technical background to create detailed plans.

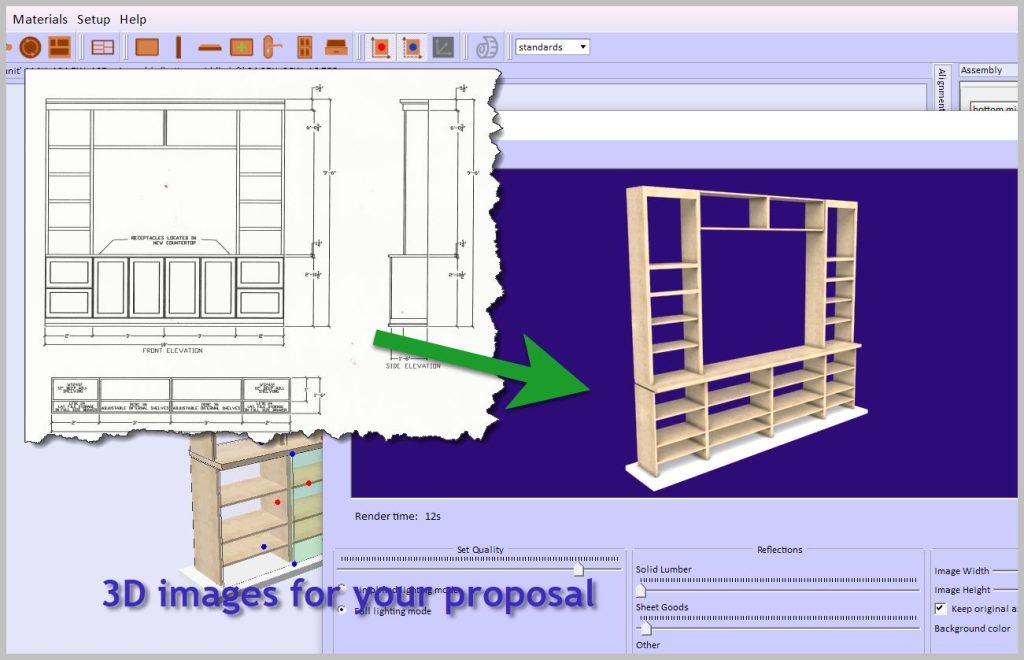

- 3D Visualization – A good app enables woodworkers to see their project in a realistic 3D model, making it easier to identify potential design flaws before cutting materials.

- Automated Cut Lists and Reports – Time is money, and an app that automatically generates cut lists and material reports can save hours of manual calculations.

- Quick Revisions – Making changes to a design should be as simple as dragging and adjusting components rather than starting from scratch.

- Integration with CNC Machines – If you use automated machinery, the app should be compatible with your tools to ensure seamless production.

The Benefits of Digital Woodworking Design

Switching to an app to draw woodworking plans isn’t just about keeping up with technology—it’s about improving efficiency, reducing waste, and enhancing the overall quality of your projects. Here’s how a digital design tool can benefit your woodworking business:

1. Faster Project Turnaround

A high-end app for woodworking design allows you to create detailed plans in minutes rather than hours. Whether designing a custom cabinet, a complex bookshelf, or an intricate furniture piece, the speed at which you can adjust and refine designs directly translates into faster production times.

2. Improved Accuracy and Precision

Digital design tools eliminate common human errors associated with manual drafting. With precise measurements and automated calculations, you can be confident that your final product will match the initial concept.

3. Enhanced Client Communication

Showing clients a 3D rendering rather than a flat sketch helps them visualize the finished product better. This leads to fewer misunderstandings, greater satisfaction, and a higher likelihood of securing repeat business.

4. Cost Savings Through Material Optimization

An app to draw woodworking plans can help reduce material waste by optimizing cuts and layouts. Automated reports ensure you purchase only what’s needed, saving money on excess lumber and supplies.

5. Competitive Advantage in the Market

High-end woodworking businesses thrive on reputation and efficiency. By adopting modern design technology, you position yourself ahead of competitors who still rely on outdated methods.

How to Get Started with a Woodworking Design App

If you’re new to digital design, transitioning to an app for woodworking may initially seem daunting. However, many software solutions are designed with simplicity in mind. Here’s how to get started:

- Choose the Right Software – Look for an app that caters to woodworkers rather than general CAD programs.

- Watch Tutorials and Learn the Basics—Many woodworking design apps offer free training videos and tutorials to help you get started quickly.

- Start with Simple Projects – Begin by designing a basic project to get comfortable with the interface and features.

- Explore Advanced Features—Once familiar with them, utilize more advanced functions like cut list generation, joinery automation, and material cost estimation.

- Implement in Your Workflow – Integrate the software into your daily business operations to maximize efficiency.

Final Thoughts: The Future of Woodworking is Digital

As technology continues to evolve, the woodworking industry is following suit. A powerful app for woodworking design is no longer a luxury but a necessity for serious professionals and high-end hobbyists. Whether crafting custom furniture, high-end cabinetry, or complex wooden structures, a digital design tool will help you work smarter, faster, and more precisely.

By embracing an app to draw woodworking plans, you’ll save time, reduce waste, and improve customer satisfaction—ultimately leading to a more profitable and sustainable woodworking business. If you haven’t yet made the switch, now is the time to explore how modern design tools can elevate your craft.

For more see this post.

For more about SketchList 3D – read this review.