Designing Drawers: Tips and Techniques for Sturdy and Stylish Drawer Construction

Designing drawers – As a woodworker, I have always believed that a well-designed drawer is the hallmark of good craftsmanship. Drawers are an integral part of any furniture piece, and their design can either make or break the functionality and aesthetics of the furniture. In this article, I will share some tips and techniques for designing sturdy and stylish drawers that will stand the test of time.

Introduction

Before we dive into the details of designing drawers, it is essential to understand the importance of drawers in furniture design. Drawers are the primary storage component of any furniture piece, and they need to be functional, sturdy, and aesthetically appealing. A well-designed drawer should be easy to open and close, should have ample storage space, and should complement the overall design of the furniture.

Benefits of Well-Designed Drawers

Well-designed drawers offer several benefits to both the designer and the end-user. For the designer, a well-designed drawer is a testament to their craftsmanship and attention to detail. For the end-user, a well-designed drawer offers ease of use, ample storage, and adds to the overall aesthetics of the furniture piece.

Types of Drawer Construction

There are several types of drawer construction methods, and each has its pros and cons. The most common types of drawer construction methods are dovetail, dado, box, and butt joint. Dovetail joints are the most popular and are known for their durability and strength. Dado joints are another popular option and are known for their simplicity and ease of construction. Box joints are relatively easy to construct and are known for their clean lines and strength. Finally, butt joints are the simplest and are best suited for lightweight drawers.

Factors to Consider When Designing Drawers

When designing drawers, there are several factors to consider, including the size of the drawer, the weight it will be carrying, and the type of furniture it will be a part of. The size of the drawer is crucial as it determines the amount of storage space it will offer. The weight it will be carrying is also essential as it determines the type of joint that will be used. The type of furniture it will be a part of is also crucial as it determines the overall design aesthetic of the drawer.

Common Mistakes to Avoid When Designing Drawers

One of the most common mistakes that designers make when designing drawers is not considering the weight the drawer will be carrying. If the drawer is not designed to handle the weight, it will buckle and eventually break. Another common mistake is not leaving enough space for the drawer to open and close fully. This can lead to the drawer getting stuck, which can be frustrating for the end-user. Finally, not selecting the right type of joint for the drawer can also lead to its failure.

Drawer Hardware Options

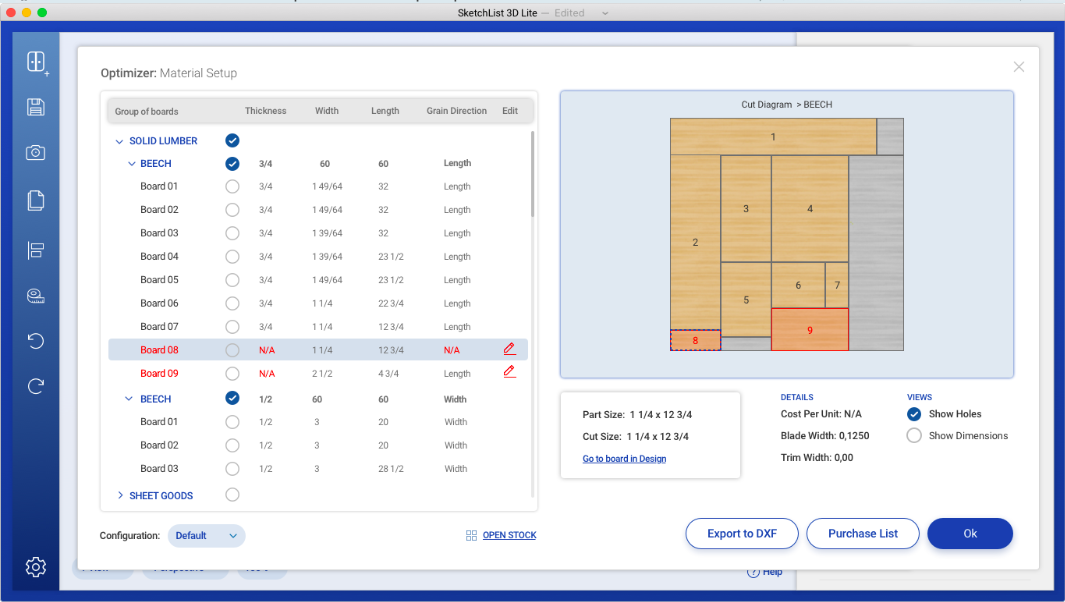

Drawer hardware is an essential component of any drawer, and there are several hardware options available. The most popular hardware options are ball-bearing slides, side-mount slides, and under-mount slides. Ball-bearing slides are known for their smooth operation and durability. Side-mount slides are relatively easy to install and are known for their affordability. Under-mount slides are the most aesthetically pleasing and are ideal for furniture pieces where the drawer is visible.

Tips for Designing Sturdy and Stylish Drawers

When designing drawers, there are several tips that can help ensure that they are both sturdy and stylish. One of the most important tips is to select the right type of joint for the drawer. Dovetail joints are the most popular and are known for their strength and durability. Another important tip is to select the right type of hardware for the drawer. Ball-bearing slides are the most popular and offer smooth operation and durability. Finally, selecting the right type of material for the drawer is also crucial. Hardwoods such as oak, maple, and cherry are ideal for drawer construction. Drawer pulls add functionality and function.

Materials for Drawer Construction

The material used for drawer construction is essential and can significantly impact the durability and aesthetics of the drawer. Hardwoods such as oak, maple, and cherry are ideal for drawer construction as they are durable and aesthetically pleasing. Plywood is another popular option and is known for its strength and affordability. Particleboard is the least preferred option and is best suited for lightweight drawers.

Drawer Design Techniques

Drawer design techniques are an essential component of any furniture piece, and there are several techniques that can be used to enhance the aesthetics of the drawer. One of the most popular techniques is adding a decorative edge to the front of the drawer. This can be achieved by using a router or by using decorative molding. Another popular technique is adding a decorative inlay to the front of the drawer. Inlays can be made from a variety of materials such as wood, metal, and stone.

Conclusion and Final Thoughts

In conclusion, designing drawers is an essential component of furniture design, and it requires attention to detail and a thorough understanding of the various factors that influence their design. By following the tips and techniques outlined in this article, designers can create sturdy and stylish drawers that will stand the test of time. Whether you are an experienced designer or just starting, designing drawers requires patience, skill, and an eye for detail. Remember to select the right hardware, material, and joint for the drawer, and always consider the weight it will be carrying. With these tips in mind, you can create beautiful and functional drawers that will last a lifetime.

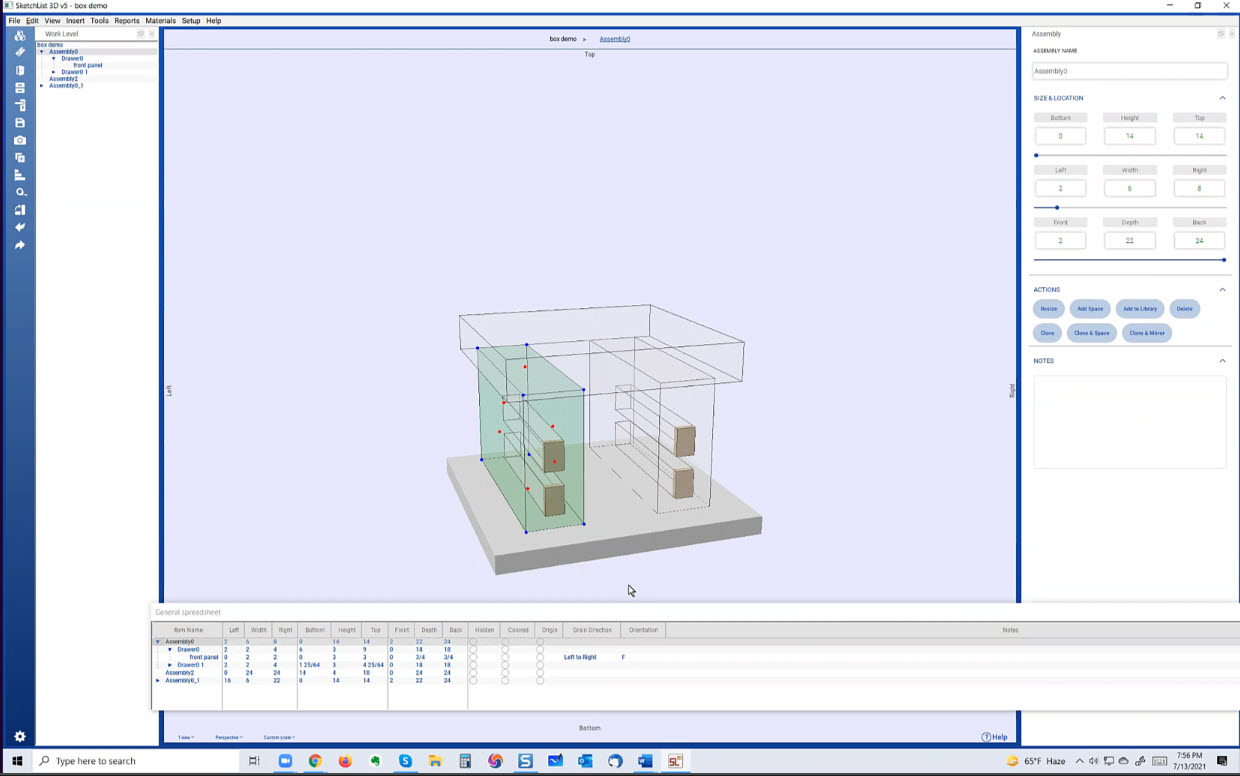

If you need assistance with designing drawers or any other furniture piece, please feel free to visit us at sketchlist.com/. SketchList 3D is the leading woodworking design software and makes designing and making high quality drawers.