Woodgrain design: When it comes to bringing a natural look to your cabinets, nothing beats the timeless beauty of introduced by careful selection of woodgrain. Woodgrain has been around since the dawn of time, and it’s a great way to add a touch of warmth and character to any space. From traditional to modern, woodgrain design can introduce a variety of ways to bring a natural look to your cabinetry.

Introduction to Woodgrain

Woodgrain is an art form that utilizes the natural patterns of wood grain to create beautiful and unique designs. The patterns of wood grain can be arranged in a variety of ways to create a wide range of designs, from abstract to geometric. Woodgrain design is not only beautiful, but it is also incredibly versatile. It can create everything from cabinetry to furniture, and even wall art.

Woodgrain is not just about the look; it is also about the feel. The grain of the wood can be manipulated to create textures that are smooth and luxurious, or rough and rustic. Regardless of the look you are going for, woodgrain can help you achieve it.

Benefits of Woodgrain

Woodgrain is a great way to add a touch of natural beauty to any space. It is a timeless look that will never go out of style. Woodgrain is also incredibly durable and can withstand the wear and tear of everyday life.

Wood is a natural and renewable resource that is both sustainable and eco-friendly. Utilizing woodgrain in your cabinetry ensures that you are not only getting a beautiful look but also helping to preserve our environment.

Types of Woodgrain

There are a variety of woodgrain designs to choose from. These designs range from traditional to modern and can create a wide range of looks. Some of the most popular woodgrain designs include:

- Traditional woodgrain: Traditional woodgrain designs feature wood grain patterns that are typical of traditional woodworking. These designs create a classic and timeless look.

- Modern woodgrain: Modern woodgrain designs feature wood grain patterns that are more contemporary. These designs create a sleek and modern look.

- Abstract woodgrain: Abstract woodgrain designs feature wood grain patterns more abstract in nature. These designs are often used to create a unique and eye-catching look.

- Geometric woodgrain: Geometric woodgrain designs feature wood grain patterns geometric in nature. These designs are often used to create a bold and stylish look.

How to Choose a Woodgrain

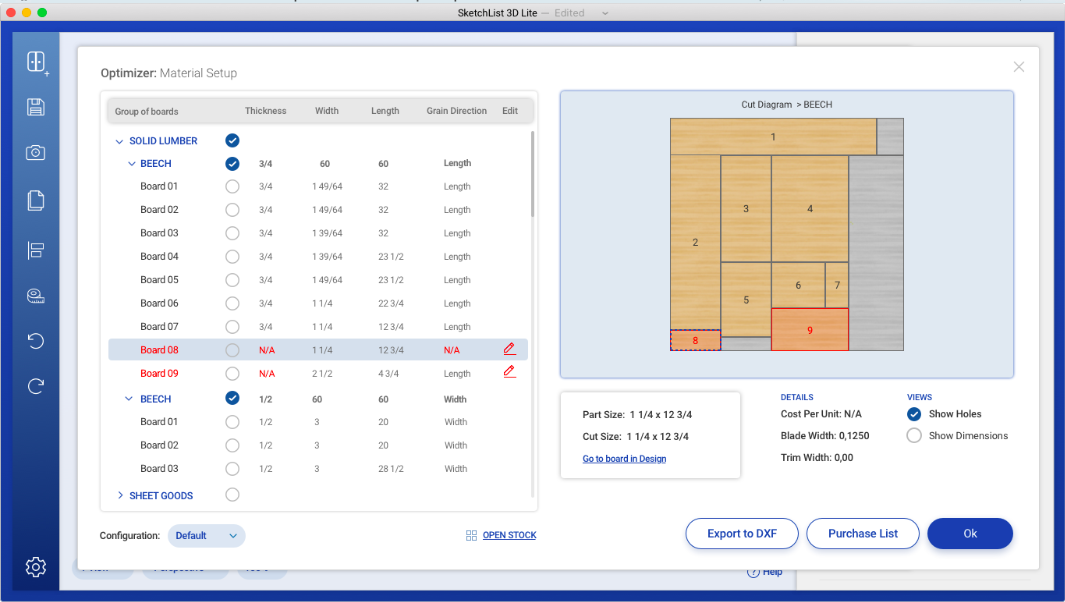

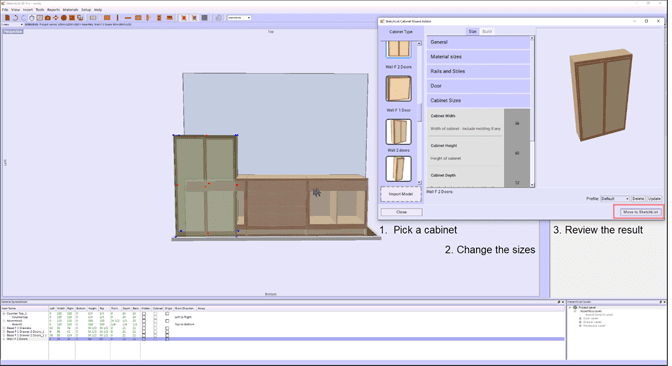

When choosing the right woodgrain for your cabinetry, it is important to consider the overall look and feel of your space. Choose a design that complements the existing décor of your home and reflects your personal style. Additionally, consider the type of wood you will be using for your cabinetry. Different types of wood will have different grain patterns, so it is important to pick a woodgrain design that complements the wood you are using.

Once you have chosen the right woodgrain design for your cabinetry, it is important to consider the installation process. Installing woodgrain design seems like a difficult and time-consuming process, so make sure you are prepared for the task.

Tips for Installing Woodgrain Design

Installing woodgrain design can be a difficult and time-consuming process, but there are a few tips that can help make the process easier.

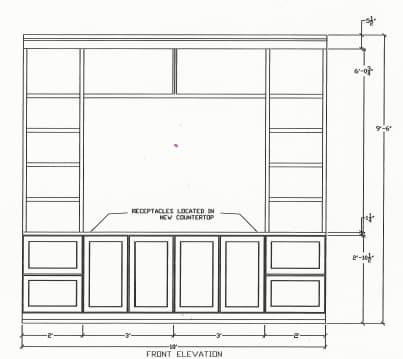

- Plan Ahead: Before you begin work in your design, it is important to plan ahead. Measure the space you have to work with and make sure you have all the materials you need.

- Take Your Time: Installing woodgrain design requires patience and attention to detail. Take your time and make sure you are following the instructions carefully.

- Use the Right Tools: Using the wrong tools can make the process much more difficult. Make sure you are using the right tools for the job.

- Test the Fit: Before you begin installing your woodgrain design, it is a good idea to do a test fit. This will help you make sure the design fits properly and looks the way you want it to.

Trends in Design

Woodgrain design is a timeless look that will never go out of style, but there are always new trends to be aware of. One of the biggest trends in woodgrain design is the use of natural materials. Natural materials such as bamboo and cork are becoming increasingly popular, as they bring a unique look and feel to any space. Additionally, the use of dark woodgrain designs is also becoming more popular. Dark woodgrain designs bring a sense of sophistication to any space and can be a great way to add a touch of luxury to your cabinetry.

Popular Woodgrain Design Patterns

Woodgrain design is an art form, and there are a variety of patterns to choose from. Some of the most popular woodgrain design patterns include:

- Herringbone: The herringbone pattern is a classic woodgrain pattern used for centuries. It is a timeless look that can bring a touch of elegance to any space.

- Chevron: The chevron pattern is a modern woodgrain pattern that is becoming increasingly popular. It features a zig-zag pattern that is both stylish and eye-catching.

- Basketweave: The basketweave pattern is a classic woodgrain pattern that is perfect for adding a touch of rustic charm to any space.

- Plank: The plank pattern is a modern woodgrain pattern that features long, horizontal stripes. It is a great choice for creating a sleek and contemporary look.

Examples of Design Projects

Use woodgrain design variety of projects, from cabinetry to furniture and even wall art. Here are a few examples of projects that can help inspire your next project:

- Kitchen Cabinets: Woodgrain is a great choice for kitchen cabinetry, as it can add a touch of warmth and character to any kitchen.

- Dining Room Table: Woodgrain design can create a stunning dining room table. The woodgrain design brings a unique and eye-catching look.

- Wall Art: Woodgrain design can create unique and beautiful wall art. The woodgrain pattern creates stunning and unique pieces of art.

- Dresser: Woodgrain can create a beautiful and unique dresser. The woodgrain pattern can create a luxurious and eye-catching piece of furniture.

Conclusion

Woodgrain is an art form that utilizes the natural patterns of wood grain to create beautiful and unique . It is a timeless look that will never go out of style, and it is a great way to add a touch of warmth and character to any space. Whether you are looking for a traditional look or a modern look, woodgrain can help you achieve the look you are going for. So if you are looking to bring a natural look to your cabinets, look no further than woodgrains. Learn more about material in SketchList 3D.