Introduction to SketchList 3D

As a furniture making using a furniture design app, I have spent a lot time in the design process. From conceptualizing a design to creating a 3D model, it can be a time-consuming and tedious process. However, with the SketchList 3D app, I have found a solution that streamlines my workflow and makes the design process more efficient.

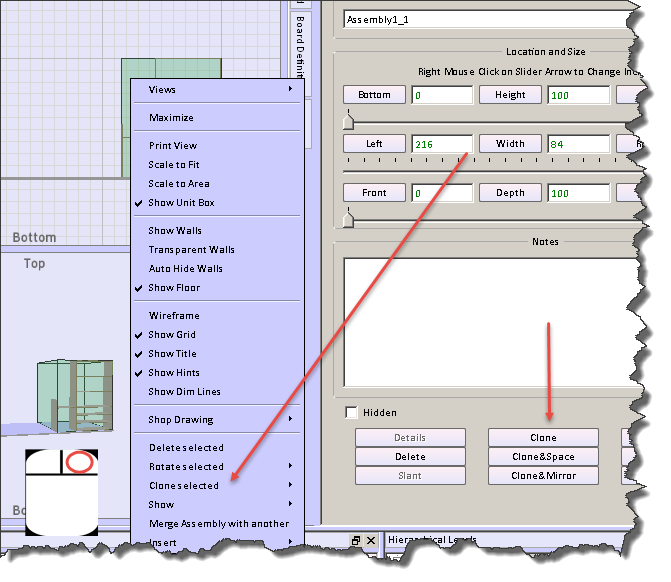

This is a project video in which a fairly complex design is done in SketchList 3D. Although a bit long at 20 minutes, it does a good job in showing the flow of the process, the way the library is used to get a quick start, and how most of the tools are used to quickly achieve your design. And remember this is a starting point from which you can explore modifications until you reach the perfect solution.

SketchList 3D is a furniture design app that has revolutionized the way I approach design. The app is specifically designed for woodworkers, furniture makers, and cabinet makers, making it the perfect tool for the job. It has a wide range of features that make designing furniture a breeze.

Benefits of using SketchList 3D for furniture design

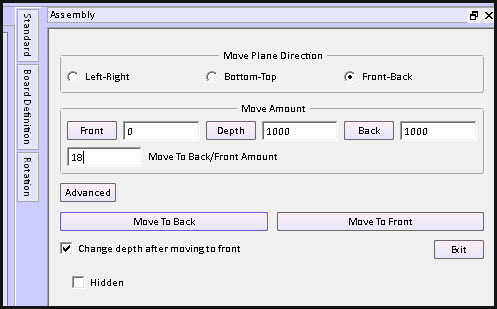

One of the main benefits of using SketchList 3D for furniture design is the time-saving aspect. With this app, I can quickly create a 3D model of my design, which saves me a lot of time. It also allows me to see my design from all angles, which helps me to spot any potential issues before I start building.

Another benefit of using SketchList 3D is the accuracy of the measurements. When designing furniture, getting the measurements right is crucial. With SketchList 3D, I can input the exact measurements of each piece of wood and get a precise 3D model. This means that I can be confident that my design will fit together perfectly when I start building.

Features of SketchList 3D app

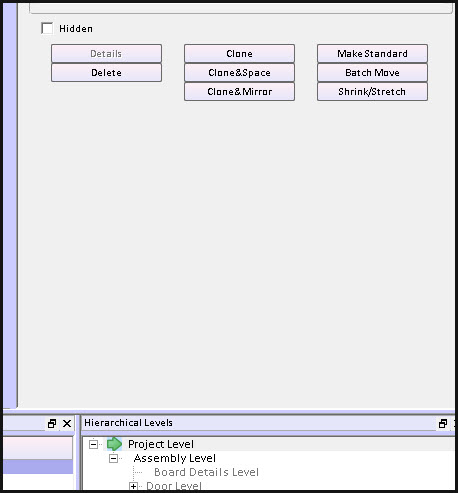

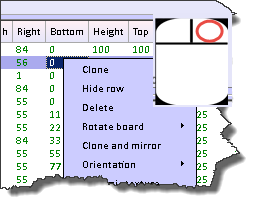

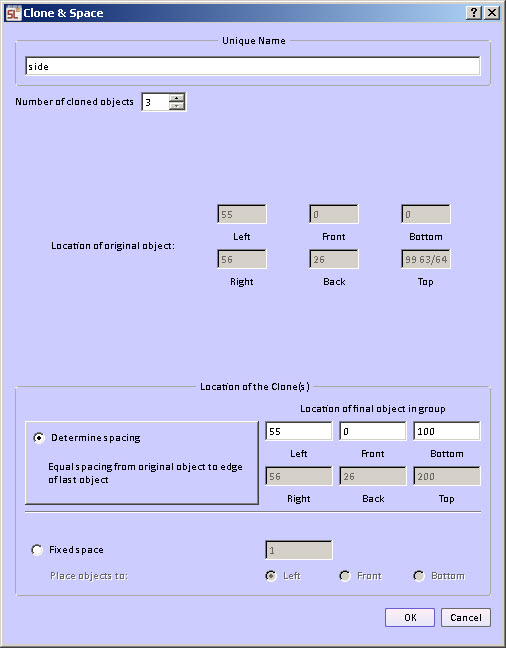

SketchList 3D has a wide range of features that make it the perfect app for furniture design. One of the key features is the ability to create a 3D model of your design. This allows you to see your design from all angles and make any necessary adjustments before you start building.

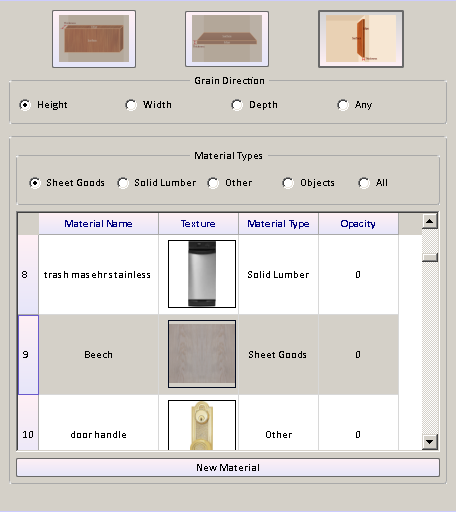

Another great feature of SketchList 3D is the ability to create a cut list. When designing furniture, it’s essential to know exactly how much wood you need for each piece. With SketchList 3D, you can input the dimensions of each piece, and the app will generate a cut list. This saves a lot of time and ensures that you have the right amount of wood for each piece.

SketchList 3D also has a 3D rendering feature, which allows you to see what your design will look like in real life. This is a great way to get a sense of how the finished product will look and make any necessary adjustments before you start building.

How SketchList 3D improves furniture design workflow

SketchList 3D has improved my furniture design workflow in several ways. Firstly, it has made the design process much quicker. With the ability to create a 3D model of my design, I can quickly see what it will look like and make any necessary adjustments. This means that I can spend more time building and less time designing.

SketchList 3D has also made the design process more accurate. When designing furniture, accuracy is crucial, and SketchList 3D ensures that my measurements are precise. This means that I can be confident that my design will fit together perfectly when I start building.

Tips for using SketchList 3D for furniture design

If you’re new to SketchList 3D, here are some tips to help you get started. Firstly, take the time to learn the app thoroughly. There are many features, and it’s essential to know how to use them all.

Another tip is to use the app to create a cut list. This will save you a lot of time and ensure that you have the right amount of wood for each piece.

Finally, be sure to use the 3D rendering feature to get a sense of what your design will look like in real life. This will help you make any necessary adjustments before you start building.

Examples of furniture design created using SketchList 3D

SketchList 3D creates a wide range of furniture designs, from simple chairs to elaborate cabinets. One example of a design created using SketchList 3D is a modern coffee table. The designer was able to quickly create a 3D model of the table, make any necessary adjustments, and then use the cut list feature to generate a list of all the wood needed.

Another example is a custom-built bookshelf. The designer was able to input the exact measurements of each piece of wood and create a precise 3D model. This ensured that the bookshelf fit together perfectly when it was built.

Comparison of SketchList 3D with other furniture design programs

There are several other furniture design programs on the market, but SketchList 3D stands out for its ease of use and accuracy. Other programs can be complicated to learn and use, which can be frustrating for beginners. SketchList 3D, on the other hand, has a user-friendly interface that makes it easy to create designs quickly and accurately.

SketchList 3D also has a wide range of features that make it a versatile furniture design app for furniture design. Other programs may have similar features, but SketchList 3D’s user-friendly interface sets it apart.

How to get started with SketchList 3D

Getting started with SketchList 3D is easy. Simply download the app and start exploring the features. There are many tutorials available online that can help you learn how to use the app effectively.

It’s also a good idea to take the time to learn keyboard shortcuts. This will save you a lot of time when designing furniture, as you won’t have to keep switching between the mouse and keyboard.

SketchList 3D resources and tutorials

There are many resources and tutorials available online to help you learn how to use SketchList 3D effectively. The SketchList 3D website has a wide range of tutorials, as well as a user forum where you can ask questions and get help from other users.

There are also many YouTube tutorials available that can help you learn how to use SketchList 3D. These tutorials cover everything from the basics of the app to more advanced features.

Conclusion

SketchList 3D is a powerful furniture design app that has revolutionized the way I approach design. Its user-friendly interface, accurate measurements, and wide range of features make it the perfect tool for furniture designers. If you’re looking for a program for furniture design, I highly recommend SketchList 3D. With this app, you can streamline your workflow, save time, and create beautiful designs with ease.