Built in storage saves space and hides junk…

Built in storage, bookcase, and entertainment centers are really in demand. Either for your personal use, or by the request of a prospect – these units are hot. They are perfect for SketchList 3D because they tend to be large and complex, offer opportunities to use objects from the library, and tend to be a design and copy type of project. A while back a survey showed us that nearly 60% of SketchList 3D users had designed at least one built in storage unit with the software.

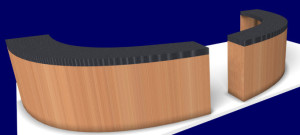

This is a great example of the type of built in storage I’m talking about. It rescues a lot of room area from a more or less otherwise hard to use corner of this bedroom. And yet it fits in perfectly. Why?

The ability to design on the computer provided the ability to try and try again with different approaches. The ability to show such great details [angled corners, molding on top. drawer fronts] at the design stage gives you a sense of what you will accomplish.

Beyond the design stage go the reports and drawings necessary to pull the finished work off.

Well heck – let me share the email from this SketchList 3D user with you.

“Just wanted to send you some of the pictures of the built-in that I designed using SketchList 3D. This was probably the largest most complex project I ever attempted and knew that I needed some drafting help. I purchased SketchList 3D and began designing. I don’t think there would have been any way for make all the design changes and construction details without SketchList 3D. What was really great was the program which optimized and laid out the cutting diagrams for all of the sheets of plywood. Rather than having to cut the 4 x 8 sheets of plywood in my small shop, I just gave them to my supplier who cut everything to size. So for a small fee, I was able to save hours of wrangling large sheets of plywood into about 100 different pieces. Thanks again for a wonderful product.”

What a great concept – asking the lumber yard to cut the sheets. I am getting too old to ‘wrangle’ 4 x 8 sheets around anymore.

Thanks for the nice feedback Mike! Question – will the dog let you pass?

If you have a design to share – send in a photo[s] and let me know what you’ve accomplished.